applicability of impact test in engineering application|types of impact testing : exporters In forging industry, the Charpy impact test can be used to determine the malleability and ductility of a material that is being forged. In the rubber industry, the test can be used for determining the shock absorbing ability of a type of rubber so that its proper application could be decided. Resultado da Maria Kaline Frequentou a instituição de ensino Escola estadual professor Luis Antônio Natal, Rio Grande do Norte, Brasil. Cadastre-se para ver o perfil Assaí Atacadista. Escola estadual professor Luiz .

{plog:ftitle_list}

Deportivo Pereira - Deportes Tolima Resultados, vídeos e est.

In forging industry, the Charpy impact test can be used to determine the malleability and ductility of a material that is being forged. In the rubber industry, the test can be used for determining the shock absorbing ability of a type of rubber so that its proper application could be decided.

The Tinius Olsen impact testers are engineered to meet the requirements of ISO 148, EN10045 -2, and ASTM E23 standards. They are widely utilized for purposes such as material acceptance, research and development, . Charpy impact testing is a low-cost and reliable test method which is commonly required by the construction codes for fracture-critical structures such as bridges and pressure . Impact testing is a critical evaluation process that determines a material or product’s toughness, resilience, and durability when subjected to sudden forces or shocks. .

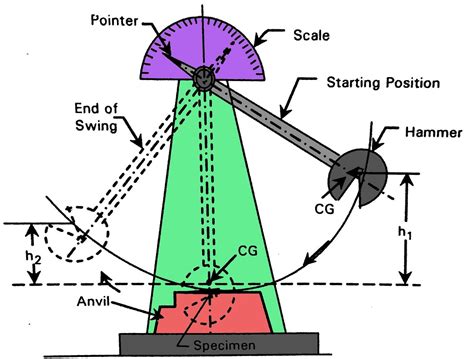

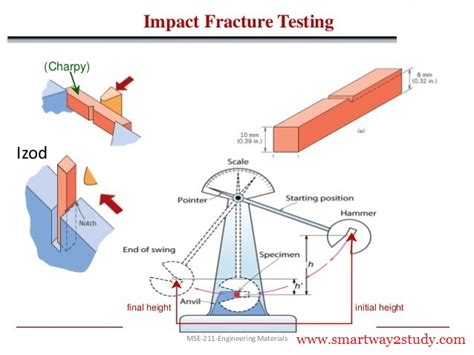

Abstract. The impact test has been used for several years, among others, for characterizing the fatigue strength, creep, adhesion and residual stresses of coatings at ambient and elevated . The Izod impact test involves striking a notched specimen with a pendulum. The energy required to break the specimen is measured and reported in units of joules per meter. The test measures the energy absorbed by the . Several testing standards exist to determine the corresponding material properties, the so-called fracture toughness (FT) in terms of KIc, JIc or similar parameters, including .Studies involving the application of the instrumented Charpy impact test are presented. The studies were concerned with the effect of strain rate, alloying, and irradiation on the ductile-brittle transition temperature (DBTT) and fracture .

According to the standard test methods, the Charpy or Izod impact test can be employed to investigate the behavior of specified types of specimens under the impact conditions defined .The concept of “good impact test” has two aspects: the quality and the applicability of the test results. The applicability of various test methods for predicting in-service performance is the subject of a companion paper.Impact test specimen types include notch configurations such as V-Notch, U-Notch, Key-Hole Notch, as well as Un-notched and ISO (DIN) V-Notch, with capabilities of impact testing sub size specimens down to ¼ size. IZOD Impact Testing can be done up to 240 foot-pounds on standard single notch and type-X3 specimens. Charpy Impact Test

Applicability of impact test. . uses and advantages in impact tests in the engineering field. We can carry those tests easily and choose the proper material for our application. Impact Test types.There are two basic ways in which the impact tests can be performed: noninstrumented or instrumented. A noninstrumented impact test only measures the energy required to break the specimen, whereas an instrumented impact test also measures the force history during the impact, see figure 2.21. In the instrumented impact tests, the pendulum’s .Applicability and limitations of impact echo (IE) in bridge deck condition monitoring, with respect to delaminations, is examined through an extensive numerical study using finite elements. . A parametric study addresses effects of the following parameters on the results of the IE test: size, depth and location of a delamination, relative to . Although its use in dynamic applications has been more limited, 3D DIC has been applied to Koskly bar testing [11, 12], terminal ballistics [13,14,15], blast [16, 17], and even Taylor impact testing studies . The only drawback of applying high-speed stereo DIC to high-rate phenomena (e.g., Taylor test) is the limited temporal and spatial .

The Impact-Echo (IE) test is an effective method for determining the presence, depth, and area of cracks in concrete as well as the dimensions of the sound concrete without defects. In addition, shallow delamination can be measured by confirming a flexural mode in the low-frequency region. Owing to the advancement of non-contact sensors and automated .

The application of Charpy Impact Test is crucial to identify whether the material being tested is suitable for a particular kind of product or not. The different materials, including forged parts . The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. Charpy impact testing determines the impact energy of materials. 1 INTRODUCTION. Systems engineering (SE) is an inherently interdisciplinary field. The body of knowledge and curriculum to advance systems engineering project (BKCASE) has developed a graduate reference curriculum for systems engineering (GRCSE) that, as its name suggests, is meant to codify a curriculum that will prepare SE students for the .

what is impact testing

Impact testing is a type of mechanical testing used to determine how a material responds to high strain-rate loading. It involves instrumented equipment measuring loads and energy absorbed by the material when it fractur es. The results help to determine the notch toughness of the material and its suitability for a given application.An overview of mechanical and physical testing of composite materials. N. Saba, . M.T.H. Sultan, in Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, 2019 1.2.3 Impact test. The impact test is designed to determine how a specimen of a known material such as polymers, ceramics, and composites will respond to a .

While an impact test can help characterize a material’s ability to withstand sudden loads, the impact test does not account for real-world loading applications or cyclical loads. Still, the test enables the easy comparison of impact strengths between materials, so long as the materials were tested with the same standard.

mechanical properties of the material to select the material for the engineering applications. Keywords: Strength, hardness, mechanical property, toughness, elasticity, . The factors responsible for the Charpy impact test are ductility, yield strength, notch, temperature, and fracture mechanism. Figure 3, shows the working procedure of impact . Brinell Hardness Test: Diagram of Brinell Hardness Testing Machine. Brinell Hardness Test is one of the most important hardness tests in the engineering industry and metallurgy. It is used when the surface of the metal is very rough to use another hardness test on it. There are two methods to perform the Brinell hardness Test on the metal as . The traditional soil stabilization techniques, which primarily include calcium-rich additives, are gradually replaced by environmentally friendly techniques as the former increases the carbon footprint emissions. On the other hand, nanomaterials (particles with a size range of less than 100 nm) are gaining acceptance in geotechnical and geoenvironmental engineering .

Abstract. This paper is focused on the approximation of absorbed Charpy impact energy-temperature curves (KV-T) and the management of sub-size test piece results in Charpy pendulum impact tests. Both subjects are frequently underestimated but may have a strong impact on the assessment of product quality and structural integrity. The status of related test . The Brazilian test is extensively used to indirectly measure the tensile strength of rock. However, the Brazilian tensile strength (BTS) does not always align with the direct tensile strength (DTS), resulting in a lack of .International Journal of Engineering Research and Applications www.ijera.com ISSN: 2248-9622, Vol. 11, Issue 10, (Series-IV) October 2021, pp. 59-63 . Charpy Impact Test on Mild Steel (Mohammad Jassim Hussain) ABSTRACT The overall purpose of this research is to explore the usage of an impact testing machine, specifically the Charpy .

The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic impacts. Even as businesses change, the Charpy impact test is still a valuable and essential tool. With the increasing effect of urbanization becoming more apparent through flooding and decline in downstream water quality especially from heavy rainfalls, stormwater runoff management solutions have focused on treatment and infiltration. However, there are areas with low infiltration soils or are experiencing more dry days and even drought. In this study, . Polyvinyl alcohol fibre (PVA fibre, as shown in Fig. 1) is superior to other fibres such as polypropylene fibre or polyester fibre in engineering applications because of its higher strength, lower elastic modulus, lower fracture elongation, and, especially, more effective cohesion with cement.The physical and mechanical performance indicators of PVA fibre are . The inertia wheel impact testing method shown in Figure 4(c) is similar to the pendulum testing method, but it provides more consistent and higher impact velocities of up to 20 m/s. This method is able to conduct medium velocity impact testing (Loureiro et al. Citation 2010; You et al. Citation 2020).

The chip impact test was originally developed in order to measuring the effect of surface microcracking caused by the weathering. The toughness of the material is measured in this test as opposed to the material notch . easily applicability, short testing time and low consumption of materials during the test. But, on the other side, its .

types of impact testing

Crush Tester vendor

teraction between testing and construction, design and performance can likewise interact more closely with the consequent better exploitation of materials. TEST PROCEDURE The impact soil test was developed to assist with an evaluation of low-volume roads in Western Austra-1 ia.

Application of the instrumented impact test to the toughness characterization of high impact thermoplastics . successfully describes the fracture properties of brittle polymers and its applicability is well established for different strain rates (static, dynamic, fatigue).2"6 How- ever, many polymers exist in which significant plastic .Studies involving the application of the instrumented Charpy impact test are presented. The studies were concerned with the effect of strain rate, alloying, and irradiation on the ductile-brittle transition temperature (DBTT) and fracture behavior of pressure vessel steels. In civil engineering, carbon fibre-reinforced polymer (CFRP) composites have emerged as a promising alternative to conventional materials. The article provides a comprehensive overview of the application of CFRP composites in various building structural elements and their characteristics and properties, such as their fatigue and corrosion .

Paper core Crush Tester vendor

charpy impact test applications

web17 de set. de 2023 · O Sorteio Viva Sorte está marcado para hoje, domingo, 17/09/2023, e terá início às 11:00hrs. A transmissão acontecerá na TV BAND, para todo o Brasil. Não perca a chance de acompanhar ao vivo e torcer para ser um dos sortudos ganhadores! A apresentação do sorteio será conduzida pelo carismático Renato Ambrosio, garantindo .

applicability of impact test in engineering application|types of impact testing